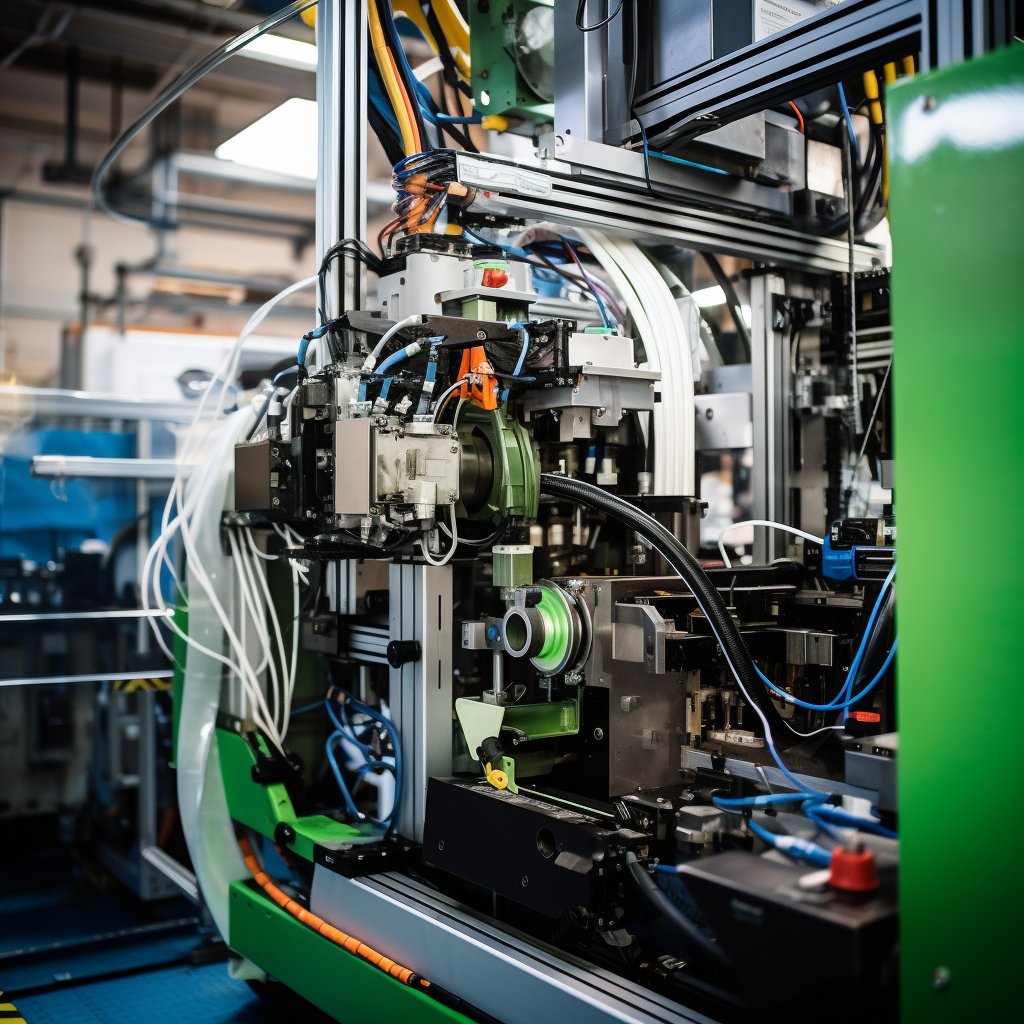

Plastic Blow moulding is a manufacturing process that produces hollow plastic parts by inflating a heated plastic tube or preforming inside a mould. The technique is widely used in the plastics industry to create various consumer products, industrial parts, and packaging containers.

Several types of plastic blow moulding techniques are used in the industry, including extrusion blow moulding, injection blow moulding, stretch blow moulding, and rotational blow moulding. Each of these techniques has unique advantages and is used in specific applications.

Plastic blow moulding has become a crucial part of the plastics industry, revolutionising the manufacturing of hollow plastic products such as bottles, containers, and other plastic products. Its cost-effectiveness and design flexibility have made it popular for producing customised products in various industries, from automotive to consumer goods. However, the impact of plastic blow moulding on the environment and global economy has become a growing concern, with plastic waste pollution and increasing regulatory scrutiny affecting manufacturers.

Extrusion Blow moulding

Extrusion blow moulding is a manufacturing process that produces large quantities of simple plastic parts, such as bottles and containers. In this process, plastic is melted and extruded into a hollow tube, then inflated inside a mould to create the final product. The packaging industry widely uses the technique to produce containers for food, beverages, and household products.

Injection Blow moulding

Injection blow moulding is a process that is used to produce small, high-precision plastic parts, such as medical equipment and electronic components. In this process, plastic is injected into a mould to create a preform, which is then inflated inside the same mould to make the final product. The technique is widely used in the medical and electronics industries.

Stretch Blow moulding

Stretch blow moulding is a process used to produce high-quality plastic containers, such as PET bottles for beverages and personal care products. In this process, a preform is heated and stretched in axial and radial directions to produce a finished container with high clarity and strength.

Rotational Blow moulding

Rotational blow moulding is a process used to produce large, complex plastic parts, such as fuel tanks and industrial containers. In this process, a hollow mould is rotated around two perpendicular axes, while plastic is added to the mould as powder or pellets. The mould is then heated and spun to distribute the plastic evenly, creating a finished product.

Industrial Usage and Application Areas

Plastic blow moulding is widely used in packaging to produce containers for food, beverages, and household products. The technique is also used to make a variety of industrial parts, such as fuel tanks, automotive parts, and medical equipment.

Consumer Product Examples

Plastic blow moulding is used to produce a variety of consumer products, including:

- Bottles and containers for beverages, personal care products, and household products

- Automotive parts, such as fuel tanks and bumpers

- Medical equipment, such as syringes and IV bags

- Toys and games

- Sports equipment, such as footballs and soccer balls

Material Properties

Plastic blow moulding can be used with a variety of thermoplastic materials, including:

- Polyethene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Polycarbonate (PC)

- Polyethene terephthalate (PET)

The material properties of these plastics can be varied to produce different characteristics in the finished product, such as flexibility, strength, and clarity.

Future Trends in Recycling

Plastic blow moulding is a popular manufacturing process that produces much plastic waste. In recent years, there has been a growing concern about the environmental impact of plastic waste and the need for more sustainable manufacturing processes.

The global market for plastic blow moulding is expected to grow steadily in the coming years, driven by the increasing demand for consumer products, industrial parts, and packaging containers. The growing focus on sustainability and the development of recycling technologies are expected to influence the future market dynamics of plastic blow moulding.

The use of biodegradable and compostable plastics in blow moulding processes is also expected to gain traction in the coming years as consumers and governments become more environmentally conscious. These materials can help to reduce the environmental impact of plastic blow moulding by breaking down more quickly than traditional plastics.

Plastics impact the global plastics industry. The market price of plastic blow moulding products is influenced by factors, including the cost of raw materials, competition, and technological innovation. Recycled materials and sustainable manufacturing processes are expected to influence the market dynamics.

Market Price Developments

Several factors, including the cost of raw materials, labour, energy, and transportation, influence the market price of plastic blow moulding products. The prices of raw materials used in plastic blow mouldings, such as PE, PP, and PVC, have been volatile in recent years due to fluctuations in supply and demand, geopolitical tensions, and other market factors.

The prices of plastic blow moulding products are also influenced by the level of competition in the market, with intense competition leading to lower prices. In addition, innovations in technology and manufacturing processes can also impact the market price of plastic blow moulding products.

Global Impact

Plastic blow moulding significantly impacts the global plastics industry, with the technique used to produce a variety of consumer products, industrial parts, and packaging containers. However, the high volume of plastic waste generated by the manufacturing process has raised concerns about the environmental impact of plastic blow moulding.

The global plastic waste crisis has led to a growing interest in sustainable manufacturing processes and the development of recycling technologies. Using recycled plastic materials in blow moulding processes can help reduce the environmental impact of plastic blow moulding by decreasing the amount of plastic waste generated.

Environmental Impact

The environmental impact of plastic blow moulding has been a subject of concern for many years. The manufacturing process generates significant plastic waste, which can take hundreds of years to decompose, polluting the environment and endangering wildlife.

Furthermore, plastic waste in oceans and landfills has contributed to global environmental pollution, leading to increased awareness and calls for sustainable manufacturing practices.

However, using recycled plastics in blow moulding processes can help reduce the environmental impact of plastic blow moulding. Recycling plastic bottles, for instance, can save up to 70% of energy costs compared to using virgin materials. Additionally, biodegradable and compostable plastics are gaining popularity, which can help reduce plastic waste.

Economic Impact

Plastic blow moulding has had a significant economic impact around the world, contributing to the growth of the plastics industry. The use of blow moulding techniques in various industries, such as automotive, construction, packaging, and consumer goods, has created numerous jobs and businesses.

Additionally, innovative blow moulding technologies have enabled manufacturers to produce high-quality products more efficiently, leading to increased productivity and profitability.

However, the global plastic waste crisis has also led to increased regulatory scrutiny and increased costs for manufacturers. Governments and consumers are demanding more environmentally friendly and sustainable manufacturing practices, which could increase the costs of production and reduce profitability.

Blow Moulding:

Plastic blow moulding has revolutionised the manufacturing of hollow plastic products, providing a cost-effective and design-flexible solution for various industries. However, as plastic waste pollution and increasing regulatory scrutiny continue to impact the environment and global economy, it is important for manufacturers to consider the use of recycled and biodegradable plastics in their production processes. With ongoing advancements in materials science and technology, the future of plastic blow moulding is promising, and we can expect to see continued innovation in the industry.

Plastic blow moulding has significantly impacted the global plastics industry, both environmentally and economically. The manufacturing process generates a significant amount of plastic waste, which can be harmful to the environment, but the use of recycled and biodegradable plastics can help reduce this impact. Additionally, plastic blow moulding has created numerous jobs and businesses and contributed to the growth of various industries. However, the increasing demand for sustainable manufacturing practices may increase costs and reduce profitability, highlighting the need for manufacturers to find innovative solutions to balance environmental concerns and economic growth.