Extrusion moulding is a widely used process in the plastics industry that involves the creation of products with consistent cross-sectional profiles. This process is used in a variety of applications, including packaging, construction, and consumer products.

Extrusion moulding is a widely used manufacturing process in the plastics industry, and it plays a crucial role in creating products that we use every day. From packaging materials to pipes and tubing, extrusion moulding is used to produce a wide range of products that are essential to modern life. However, as with many industrial processes, extrusion moulding has environmental and economic impacts that must be considered.

Types of Extrusion Moulding:

There are several types of extrusion moulding processes, including:

- Blown Film Extrusion: This process involves the creation of plastic films, typically used in packaging applications.

- Sheet Extrusion: Sheet extrusion is used to create plastic sheets that can be further processed into various products such as thermoformed containers, trays, and other products.

- Co-Extrusion: Co-extrusion involves the use of multiple extruders to create products with multiple layers, each layer having different material properties.

- Profile Extrusion: Profile extrusion is used to create products with specific cross-sectional shapes, such as pipes, tubing, and other products.

Industrial Usage:

Extrusion moulding is used in packaging, construction, and transportation. In the packaging industry, extrusion moulding creates plastic films, bags, and containers. In the construction industry, extrusion moulding makes pipes, tubing, and other building materials.

Application Areas:

Extrusion moulding has a wide range of application areas. Some of the most common areas include:

- Packaging: Extrusion moulding is used to create plastic films, bags, and containers used in the food and beverage, pharmaceutical, and other industries.

- Construction: Extrusion moulding is used to create pipes, tubing, and other building materials used in construction applications.

- Transportation: Extrusion moulding creates components for automobiles, airplanes, and other vehicles.

Consumer Product Examples:

Extrusion moulding is used to create a variety of consumer products. Some examples include:

- Plastic bags and containers for food storage and transportation.

- Plastic tubing and pipes for irrigation and plumbing applications.

- Automotive components such as weatherstripping and fuel lines.

Material Properties:

Extrusion moulding allows for the creation of products with specific material properties. Some of the most common materials used in extrusion moulding include:

- Polyethylene: This material is commonly used in the packaging industry due to its flexibility and durability.

- PVC: PVC is commonly used in the construction industry due to its fire-resistant properties.

- Polycarbonate: Polycarbonate is commonly used in the transportation industry due to its strength and durability.

Future Trends in Regards to Recycling:

The future of extrusion moulding looks promising, but it also faces significant challenges. The industry is expected to adopt sustainable practices to address the increasing concerns about plastic waste. Future trends in extrusion moulding include the use of bioplastics, which are derived from renewable resources, and the development of new recycling technologies to increase efficiency and reduce waste.

Another key trend is the adoption of Industry 4.0 technologies, which involve data analytics, artificial intelligence, and robotics to optimise production processes, reduce waste, and increase efficiency. Integrating digital technologies into the extrusion moulding process is expected to enhance product quality, reduce production costs, and improve the industry’s overall competitiveness.

As sustainability becomes an increasingly important issue, recycling is becoming more prevalent in the plastics industry. Future trends in recycling include:

- Increased use of recycled materials in extrusion moulding processes.

- Development of new recycling technologies to increase efficiency and reduce waste.

- Collaboration between industry stakeholders to develop sustainable practices.

Extrusion moulding is a key process in the plastics industry. Its market value is expected to grow due to the increasing demand for plastic products across various industries. This section will look at the different extrusion moulding methods, their market price developments, global impact, and future market prognosis.

Market Price Developments:

The global extrusion moulding market is expected to grow steadily over the next few years. According to a report by MarketsandMarkets, the global extrusion moulding market size is projected to reach $10.4 billion by 2025, with a CAGR of 3.9% from 2020 to 2025. The growth is attributed to the increasing demand for plastic products across various industries such as packaging, construction, and transportation.

The market price of extrusion moulding products is affected by several factors, including raw material costs, energy costs, labor costs, and market demand. Raw material costs, in particular, significantly impact the market price of extrusion moulding products. The prices of raw materials such as resins, additives, and colorants are subject to fluctuations based on market supply and demand, geopolitical factors, and natural disasters.

Global Impact:

Extrusion moulding has a significant global impact, both positive and negative. On the positive side, extrusion moulding creates products that provide convenience and safety in various applications. For instance, plastic packaging products prevent food spoilage, preserve the quality of medicines, and protect fragile products during shipping.

However, extrusion moulding also has negative impacts, primarily related to its contribution to plastic waste. According to a report by the Ellen MacArthur Foundation, plastic production is expected to double by 2040, and the annual amount of plastic waste generated is projected to triple by 2060. The improper disposal of plastic waste has serious environmental consequences, including ocean pollution, harm to wildlife, and negative impacts on human health.

The environmental and economical impact of extrusion moulding around the world:

Extrusion moulding is a widely used manufacturing process that significantly impacts the global economy and the environment. In this section, we will examine the environmental and economic impact of extrusion moulding worldwide.

Environmental Impact:

The environmental impact of extrusion moulding is primarily related to the production and disposal of plastic products. The production of plastics involves the use of fossil fuels, which contributes to greenhouse gas emissions and climate change. The disposal of plastic waste also poses a significant environmental threat, as it can take hundreds of years to decompose and can harm wildlife and ecosystems.

However, extrusion moulding also has some positive environmental impacts. For instance, the use of plastic packaging can help to reduce food waste and extend the shelf life of products. Additionally, the recycling of plastic products can help to conserve resources and reduce waste.

Economic Impact:

Extrusion moulding has a significant economic impact around the world, as it is used in many industries and applications. The production of plastic products generates revenue and creates jobs in manufacturing, distribution, and sales. The use of plastic products also has economic benefits, such as reducing shipping costs and improving product quality.

However, extrusion moulding can also have negative economic impacts, particularly related to the disposal of plastic waste. The cost of managing and disposing of plastic waste can be significant, and the environmental damage caused by plastic waste can have economic consequences, such as lost revenue in the tourism industry.

In recent years, there has been increasing pressure on the extrusion moulding industry to address its environmental impact and adopt sustainable practices. This has led to the development of new technologies and processes aimed at reducing waste and improving resource efficiency. For instance, some manufacturers are exploring the use of biodegradable and compostable plastics, as well as the use of recycled materials in the production process.

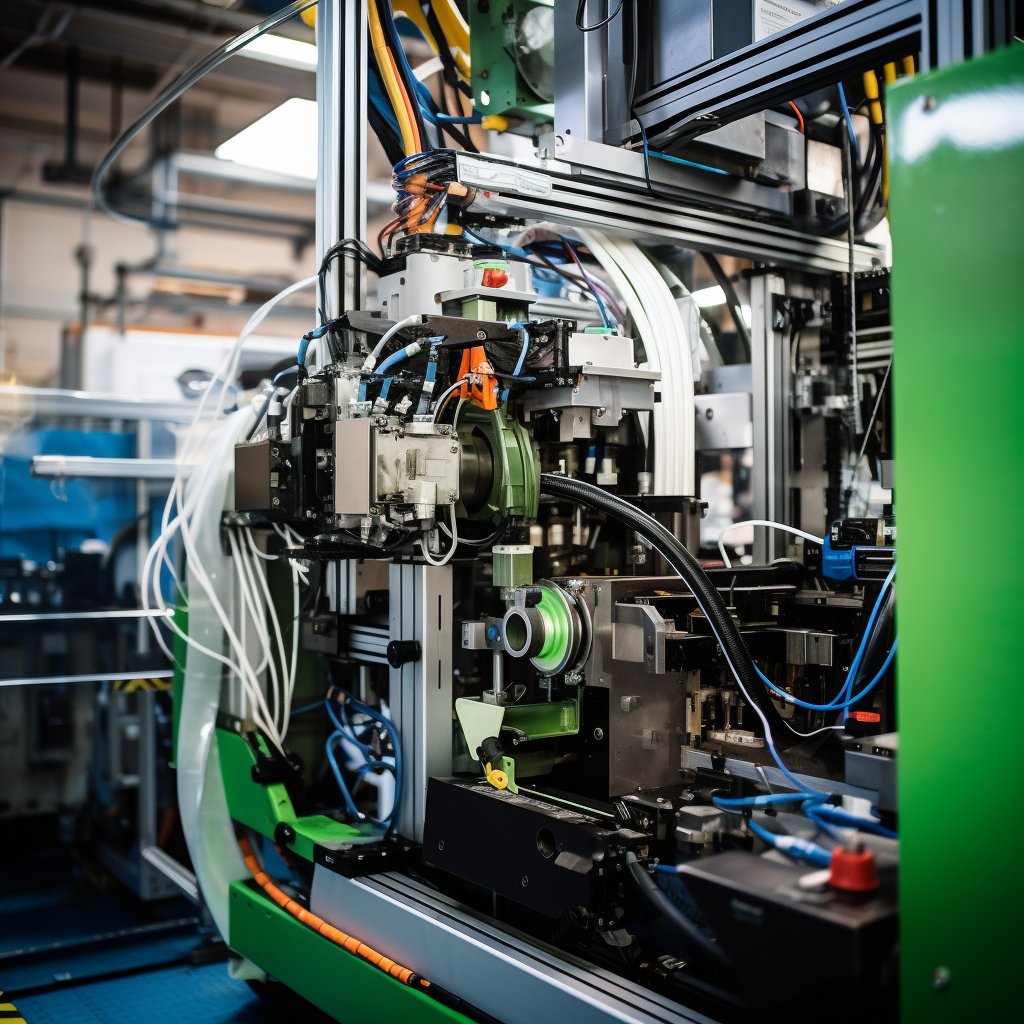

Extrusion moulding Process:

Extrusion moulding is a process that involves forcing molten plastic through a die to create a continuous profile of the desired shape. The process involves heating plastic granules in a hopper until they melt, then forcing the molten plastic through a die that shapes it into the desired form. Once the plastic has cooled and solidified, it is cut into the desired length.

Advantages of Extrusion moulding:

One of the primary advantages of extrusion moulding is that it can produce long, continuous profiles with consistent cross-sections. This makes it ideal for producing products such as pipes, tubing, and packaging materials. Additionally, extrusion moulding can create complex shapes and profiles, which can be difficult or impossible to produce using other manufacturing processes.

Another advantage of extrusion moulding is its relatively efficient and cost-effective manufacturing process. The equipment used for extrusion moulding is relatively simple and can be operated with minimal manual labor. Additionally, the process can be automated to further reduce labor costs and increase production efficiency.

Disadvantages of Extrusion moulding:

Despite its many advantages, extrusion moulding also has some disadvantages. One of the primary disadvantages is that it is limited in the types of materials that can be used. For example, thermoplastics are commonly used in extrusion moulding, but this method cannot process other materials, such as thermosets.

Another disadvantage of extrusion moulding is that it can produce waste and emissions during the production. The use of fossil fuels to heat the plastic granules can generate greenhouse gases and contribute to climate change. Additionally, the disposal of plastic waste can have negative environmental impacts, as discussed earlier.

Extrusion moulding:

Extrusion moulding is a widely used process in the plastics industry that allows for the creation of products with consistent cross-sectional profiles. This process is used in a variety of applications, including packaging, construction, and transportation. As sustainability becomes an increasingly important issue, recycling is becoming more prevalent in the plastics industry, and extrusion moulding is no exception. By adopting sustainable practices, the plastics industry can create products that meet the needs of consumers while also reducing waste and protecting the environment.